Built on a solid foundation

Since opening in 1985, SFI has strived to build trusting relationships with our customers by focusing on what we consider to be most important:

- Honesty and good communication

- Respecting project schedules

- Loyal partnerships

- Quality workmanship

- Competitive pricing

- Safe work practices

Growing from just three employees in 1985 to about 200 personnel today, we attribute our continued growth and success to our dedicated employees, our company-wide commitment to these core values and a desire to be the best at what we do.

1985-1994

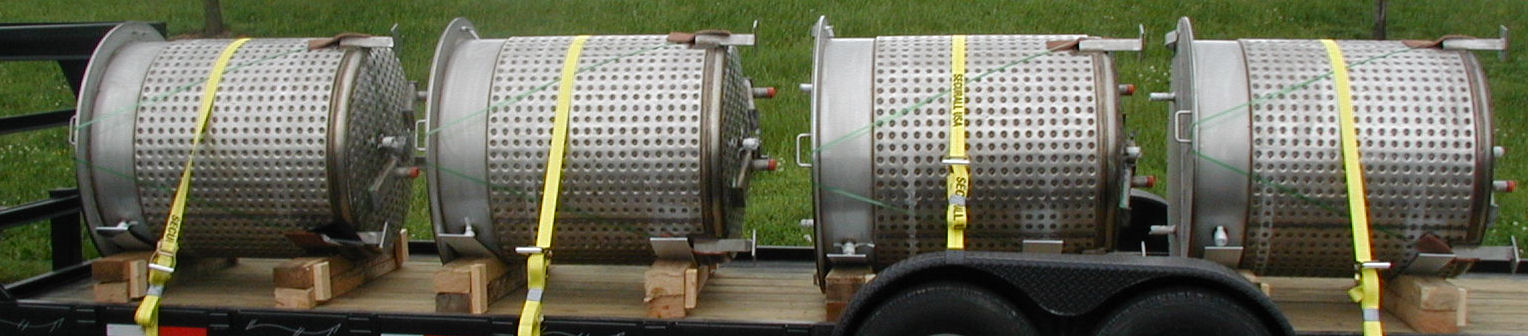

1985 – SFI opened its doors in May, with the three owners building stainless tanks in the field.

1986 – Numerous field hands were hired, many of which are still working at SFI today.

1987 – Additional personnel were hired, shop fabricated tank capabilities were added.

1988 –ASME “U” certification was obtained.

1992 – By this time, SFI had experienced substantial growth occupying five buildings on the East side of Springfield.

1993 – Construction was complete and SFI moved into their new 30,000 square foot production facility with 7,200 square feet of office space. The building sits on 17 acres, providing room for future expansion, as well as easy access to the airport and Interstate 44.

1993 – NBIC “R” certification was obtained allowing SFI to make repairs and alterations in both the shop and field.

1995–2004

1995 – A separate warehouse and two additions to the original shop building occurred between 1995-1998, adding more than 22,000 square feet of production floor.

1997 – Non-destructive examination capability was brought in-house with the addition of radiography equipment. Designated personnel were trained and certified to x-ray welds as required by customer specifications and code.

2003 – The Electropolish Bay was added and brought with it growth opportunities into the biopharmaceutical industry. The building expansion included a 15,000 square foot production bay that is segregated from the rest of the plant with electropolish finishing equipment at one end.

2005–2014

2006 – The existing plasma burner was replaced with a CNC Plasma Burn Table and a Haas Precision CNC Lathe was purchased.

2008 – SFI was purchased by Exchange Income Corporation., of Winnipeg, Manitoba, providing opportunities for growth and expansion into new markets and geographical regions.

To quickly meet the demand for more production space, SFI leased a 25,000 square foot building across the street from the main facility.

2009 – A VoIP phone system upgrade linked all buildings for both phones and network connectivity.

2010 – A large capacity Omax Jet Machining Center was purchased allowing for improved processes and efficiencies.

2013 – Cost-savings and efficiencies were improved with the addition of a crane and yard truck with a 40’ trailer allowing large tanks to be moved around the facility without bringing in an outside vendor.

2014 – A 45’ x 20’ hydro pad was built, allowing large tanks to be hydro tested standing up.

2015–2019

2015 – Our 1,800 square foot multipurpose building was completed, housing Quality Control, the Field Operations Manager, Maintenance Manager, Safety Manager and Marketing. It also has a conference room, providing us with a total of three for meetings, customer visits and FATs.

New welding equipment was purchased to reduce cost of consumables and increase efficiencies.

2016 – Fabrication equipment was purchased including a new Seam Welder and a Vertical CNC Machining Center.

SFI launches new responsive website in June 2016.

2017 – Overhead crane installed in machine shop to service CNC machining center, CNC lathe and other equipment.

2018 – New welding and grinding equipment installed and operational. A second CNC machining center was added to the machine shop, giving us four machines total for making parts and components.

Tank assembly capacity increased by 25,000 square feet when a second off-site building was leased in January.

2019 - New shear for sheet and plate material installed and operational. New, heavy duty dust collection system for sand blast room.

2020–Present

2020 - Sand blast room upgraded with a highly efficient reclaiming system.

2021 - Expansion of the outdoor stand-up and fabrication area. Upgrades to storage areas on property.

2022 - A machine shop upgrade added a new CNC vertical mill. Two new 5-ton cranes were installed in the preprocessing bay for material handling. Cranes have been upgraded to remote-controlled.

2023 - Field upgrades: A new truck and two trailers were purchased for the Field. 111 hoists were replaced with new, remote controlled units.

Shop upgrades: A new 5-ton overhead crane was installed at Shop 2.

The shop-offices were updated with paint, new furniture and equipment. The SFI welding school built new stainless steel tables and counters for the main shop breakroom. 20 new chairs and 10 bar stools were purchased along with new refrigerators, microwaves and big screen TV's.

2024 - Plans are to add a generator that will run the office during a power outage and to add an open-air material handling bay to the shipping/receiving warehouse area.

♦ ♦ ♦ ♦ ♦

Today, SFI employs nearly 200 people and we have more than 125,000 square feet of production floor. Our vessels can be found in every state in the continental U.S. and in several foreign countries. We continue to grow and expand, working with customers in a wide variety of industries.

Going Forward

SFI is a growth oriented company. We enjoy the challenges that come with building different types of equipment and working with customers from a wide variety of industries. SFI personnel are constantly looking for ways to improve all facets of the business from technology (computers, software, etc.) to equipment used in fabrication processes, to the way we literally perform our jobs — whether in the field, factory or office.

We welcome opportunities to work with new customers and expand into new markets where our expertise can be utilized and we can grow.